| MAIN |

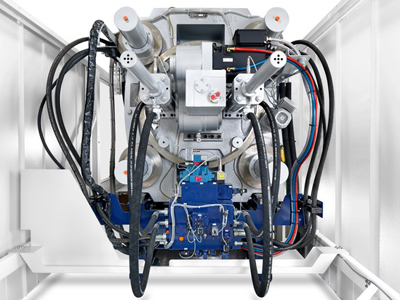

Global innovation: The ELIOS series from Netstal| Subj: Press-releses  Global innovation from Netstal. At K 2016 in Düsseldorf (19 to 26 October 2016, Hall 15, Stand B27/C24/C27/D24) Netstal will introduce the new ELIOS series with the model 7500-4200 and, with its launch, underscore its leading position in high-performance injection molding of thin-wall packaging and technical components for constructive lightweight design. The trade fair exhibit is equipped with a 24+24 stack mold for 2.8 g domed lids. The cycle time is 3.9 seconds. Global innovation from Netstal. At K 2016 in Düsseldorf (19 to 26 October 2016, Hall 15, Stand B27/C24/C27/D24) Netstal will introduce the new ELIOS series with the model 7500-4200 and, with its launch, underscore its leading position in high-performance injection molding of thin-wall packaging and technical components for constructive lightweight design. The trade fair exhibit is equipped with a 24+24 stack mold for 2.8 g domed lids. The cycle time is 3.9 seconds.High-performance injection molding in a clamping force range of 7,500 kN When developing the new series, Netstal focused on the high standards of users in the field of thin-wall packaging. "Our main intention was to close this target audience's gaping performance hole on the market in the clamping force range of 7,500 kN," said Markus Dal Pian, Netstal's Vice President Sales & Marketing. "True to our motto 'Engineering Excellence' we did not merely want to build a very fast machine. Instead, we also wanted to offer the high precision, reliability and cost effectiveness that the Netstal brand is known for and that is valued by our customers," added Dal Pian. The ELIOS 7500-4200 will run in continuous operation at K2016 in Düsseldorf: With a cycle time of 3.9 seconds, 2.8-gram polypropylene domed lids will be manufactured in a 24+24 stack mold made by the company StackTeck. The exhibit includes an automation solution from CBW Automation with integrated sorter and stacker. Patented clamping unit drive with recuperation of kinetic energy A high-performance clamping unit with a 5-point dual toggle lever is the main component of the new series. A particularly innovative and patented design for the actuation of the toggle lever is being used. "Due to the clever combination of a dynamic electro drive and a powerful hydro-mechanic assistance system, a high movement speed can be reached even with high clamping forces," explains Marcel Christen, Netstal's head of product management. As a result, the performance data of the new clamping unit is impressive: the dry cycle time is merely 1.9 seconds according to the Euromap standard. "That makes the ELIOS 7500 the fastest machine in its size class," emphasizes Christen, adding: "At the same time, ELIOS is just as precise and reliable as all other Netstal machines." The centrally aligned toggle lever ensures an optimum introduction of force into the center of the mold installation space, and hence uniform distribution of the clamping force. The extremely stable and strength-optimized design effectively prevents any deformation of the mold plates. In addition to its high speed, the new clamping unit offers an opening stroke of 1,000 mm as well as a widely spaced column distance of 1,050 mm x 1,050 mm. However, it also has another key advantage because it is able to recoup kinetic energy. The energy generated during braking processes flows into the electric motor of the main drive where it is converted into hydraulic energy and stored. "Because the energy generated in this way can be re-used in the overall system immediately, energy savings of up to 50 percent can be achieved compared to a fully hydraulic machine even during full-load operation," Christen emphasizes. Continued development of the hybrid drive technology "In order to find the optimal solution with regard to performance and energy consumption for each actuation axis, Netstal is using state-of-the-art hybrid drive technology. In doing so, the energy-technology related advantages of electric drives are combined with the high performance density of hydro-mechanical drive concepts," explains Adrian Angst, Netstal's head of Research and Development. This basic idea was consistently refined during the development of ELIOS. The clamping movement of the clamping unit can generally be divided into the two phases of movement and clamping force build up with the locking of the toggle lever. These two phases, due to their completely different characteristics, place contrasting demands on the driving actuating element. While a high dynamic and a high moving speed are required for the movement, building up the clamping force requires a great force in a very short time. For this reason, a servo-electric drive with double toothed rack design was combined with a hydro-mechanical actuation for the ELIOS. "While the electric drive guarantees a high dynamic and drive speed, the two parallel-aligned synchronized cylinders ensure the required power assistance for building up the clamping force," explains Angst further. Since the two phases of the clamping process do not take place sequentially when using a 5-point toggle lever but are synchronous instead, an incredibly precise and quickly operating controller is needed. The digital high-performance controllers that are used in the highly flexible and high-performance aXos machine control system are assuming this task. Precisely configured integration into Netstal's modular portfolio The clamping unit is complemented by proven high-performance injection units, which guarantee extreme accelerations of up to 20 G and maximum injection speeds of up to 2,200 mm/s thanks to their clever two-valve technology. The intelligent, adaptive drive modules ensure a sufficient hydraulic performance and optimal energy efficiency throughout the entire system. The ELIOS series is seamlessly integrated into Netstal's modular product portfolio. At K 2016, Netstal will introduce the series with the sizes 7500 and 6500. In 2017, additional models with clamping forces of 550 and 450 tons will follow. In total, customers will be able to choose from 33 combinations of clamping unit, injection unit and screw diameter. Due to the high flexibility of the media and the optimal accessibility of air valves, connections for hydraulic mold auxiliary controllers, cooling water distributors and sockets for the connection of peripheral devices, ELIOS can be adapted perfectly to the respective application with little effort. Due to the consistent modular design, just about any application can be implemented with this equipment toolkit. With a wide range of additional options, each machine can also be adapted to the various needs of users. Source: Netstal Previous news |

© 2002—2025 PLASTINFO