| MAIN |

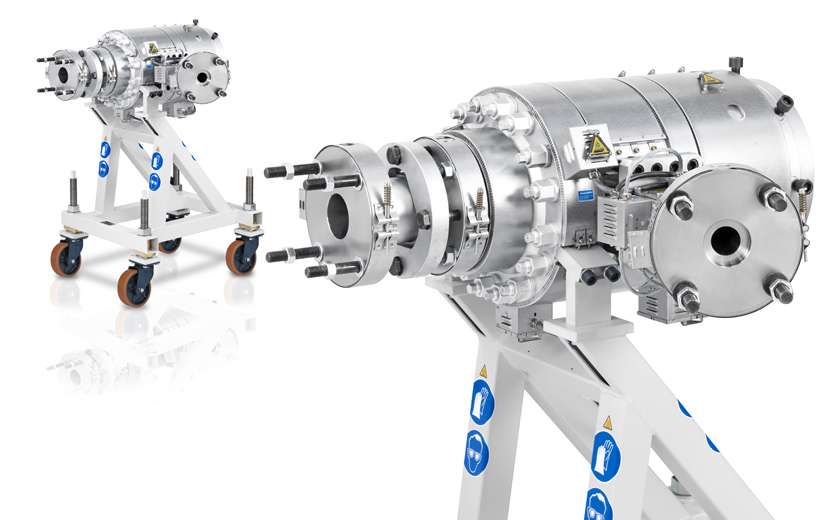

Intelligent concepts: Production of pipes with filled formulations and multifunctional layers| Subj: Press-releses  KraussMaffei Berstorff is presenting the KM-3L RK 42 modified pipe head and the KM-RK 20 S prototype, a double-compression head for small diameters, at the K 2016 trade show in Düsseldorf (October 19 to 26, 2016, Building 15, Booth B27/C24/C27/D24). Both exhibits are geared toward PVC processing. The KM-5L RKW 01-40 PO five-layer pipe head rounds out the pipe head technology product range. This pipe head is used specifically for pipe production of floor and ceiling temperature control systems. Optimized concept for processing cost-effective PVC filling material "We have given our PVC multi-layer pipe head a 'facelift' to make it more competitive in the face of increasing requirements for processing foaming formulations or recycled materials," reports Peter Roos, President of the Extrusion Technology Segment of the KraussMaffei Group and Managing Director of KraussMaffei Berstorff. Therefore, the system, which has been optimized thermally and in terms of flow technology, provides several advantages for the end product from a process technology standpoint. Generously dimensioned flow channels ensure maximum throughput. The distributor block integrated into the head ensures precise layer thickness distribution. Thanks to the compact design, a short dwell time, and thus gentle material processing, is ensured as well. In addition, the design makes handling easy during installation and removal. "When you consider that the material costs make up 70 percent of pipe production costs, our series becomes especially attractive from the standpoint of cost and sustainability. It provides the processor with maximum flexibility in using cost-effective materials such as foamed formulations, regrinds, chalk or mixtures of post-consumer material with heavily varying composition," says Roos. The KM-3L RK 42 exhibit covers the diameter range between 75 and 200 mm and is designed for an output of 800 kg/h. Small and compact: double-compression head for small dimensions The prototype of the KM-RK 20 S double-compression head serves as a perfect example of efficient production in the small diameter range. The dimensional range of the exhibit is 12 – 63 mm with a throughput of 250 kg/h. Generously dimensioned flow channels are designed for maximum throughput. The prototype is being developed further to increase pipe quality and production reliability for the future use of various customer formulations worldwide. Precision during production of multi-layered PO pipes "There is increasing demand in the PO area for complex pipes with multifunctional layers. We are meeting this demand by offering our spiral distributor system in the KM-5L RKW 01-40 5-layer pipe head," says Roos with excitement. "When it comes to these products, which are frequently used for the installation of floor and surface temperature control systems, precision and cost-efficiency are both fundamentally important," Roos states. The spiral distributor technology from KraussMaffei Berstorff is designed precisely to meet these criteria. Therefore, it guarantees excellent adhesion of the individual layers, a uniform layer thickness and low specific weights with high mechanical load-carrying ability. As a result, the finished product features the desired property patterns such as scratch resistance, diffusion resistance, temperature stability and insulation capability. The model on display is suitable for a wide variety of PO materials, such as PE-RT, PE-X and PB and extrudes pipes in the dimensional range of 8 to 40 mm with a throughput of 300 kg/h (for the inner layer). Source: KraussMaffei Berstorff Previous news |

© 2002—2025 PLASTINFO