| MAIN |

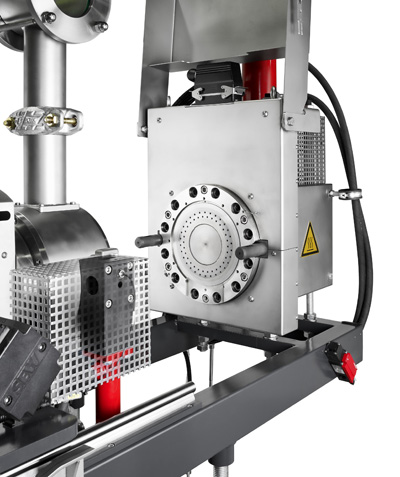

K 2016: ZE 42 BluePower twin-screw extruder for unparalleled performance and minimum energy consumption in compounding| Subj: Press-releses  At K 2016 in Düsseldorf from October 19 to 26, KraussMaffei Berstorff will exhibit another ground-breaking development – the new ZE 42 BluePower twin-screw extruder. After the successful introduction of this machine concept with its innovative technology on the world market, the ZE 42 BluePower – exhibited in operation on the booth of ECON GmbH in hall 6, booth number C55 – will produce high-intensity LLDPE colour masterbatch micro-granules with a diameter of 0.4 to 0.5 mm. At K 2016 in Düsseldorf from October 19 to 26, KraussMaffei Berstorff will exhibit another ground-breaking development – the new ZE 42 BluePower twin-screw extruder. After the successful introduction of this machine concept with its innovative technology on the world market, the ZE 42 BluePower – exhibited in operation on the booth of ECON GmbH in hall 6, booth number C55 – will produce high-intensity LLDPE colour masterbatch micro-granules with a diameter of 0.4 to 0.5 mm.Demonstration of a perfectly tailored compounding line "During the live demonstration at K 2016, we will give customers an idea of our approach to the market trend towards cost-effective compounding. With this new line, ECON and KraussMaffei Berstorff set challenging standards – not only in terms of productivity! The perfectly matched components – starting from the extruder and the pelletizer up to the drying system – give our customers outstanding cost-effectiveness in their daily routine," says Peter Roos, President of the Extrusion Technology Segment of KraussMaffei Group. The compounding line is composed of the following components: ZE 42 BluePower twin-screw extruder from KraussMaffei Berstorff, Eprotec Melt-X1 melt pump with downstream ESD70 screen changer, ECON EUP 150 underwater pelletizer and ECON EWT 250 process water system with centrifugal dryer. When used for the mentioned application, a throughput rate of approx. 70 kg/h is achieved. Substantial productivity boost with the ZE 42 BluePower The ZE 42 BluePower has been optimized for throughputs between 250 and 500 kg/h and is the ideal solution for compounding companies that focus on combining small batches, special compounds and rapid formulation changes with high productivity. "Today it's more important than ever to offer customers machines that are specifically tailored to their individual requirements in order to ensure successful market positioning and high competitiveness in changing market environments," says Peter Roos. With the extensive modular range of 4D and 6D barrel sections and different screw elements, the ZE BluePower offers the widest variety of configuration options. The unique interaction between the 1.65 OD/ID diameter ratio and the torque density of 16 Nm/ cm³ gives a substantial increase in output capacity and energy efficiency. In addition, the ZE BluePower series features various components designed to boost productivity, reliability and wear resistance: hydraulic screw pre-loading device, oval liners, improved side feeders and degassing units as well as an energy management tool. ECON downstream equipment for uncompromising process reliability and maximum availability The EUP 150 underwater pelletizer is rated for outputs ranging between 100 and 450 kg/h when processing standard pellets. The exhibited version is equipped with fine screens and special dryer blades designed for the production of micro-granular compounds. The thermally insulated pelletizing die – patented by ECON GmbH – is equipped with multi-hole die plate that is perfectly adapted to the production of micro-granules. Uniform operating concept The new operating BPCT control system with touch screen has been optimized in terms of efficiency and ergonomics and ensures uniform operation of the entire line. It offers a wide variety of configuration options for up- and downstream equipment and additional technical features. Source: KraussMaffei Berstorff Previous news |

© 2002—2025 PLASTINFO