| MAIN |

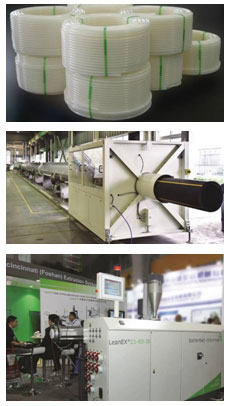

Successful Chinaplas and Open House for battenfeld-cincinnati| Subj: Press-releses  During this year’s Chinaplas, battenfeld-cincinnati China organized two demonstrations, where it presented two lines in production: a high-output (1,200 kg/h) line for 400 mm gas pipe extrusion and a LeanEX high-speed line for 20 mm PE-RT pipe that ran with a line speed of 40 m/min. Both lines showed technical competence and energy efficiency in production that sets them off from local competition. During this year’s Chinaplas, battenfeld-cincinnati China organized two demonstrations, where it presented two lines in production: a high-output (1,200 kg/h) line for 400 mm gas pipe extrusion and a LeanEX high-speed line for 20 mm PE-RT pipe that ran with a line speed of 40 m/min. Both lines showed technical competence and energy efficiency in production that sets them off from local competition.On 21 and 22 May, battenfeld-cincinnati welcomed 210 visitors at its Shunde plant for presentations and extrusion line demonstrations. Toni Bernards, CEO of battenfeld-cincinnati China comments, “We had a great show and the Open House, too, was a success. We see that the Chinese market needs both – top performance solutions for high-end applications and turnkey lines for standard products that are simple, easy to handle and quickly available. We were able to show our customers both on the booth and at the demonstration in our plant that we can do both and thus are able to deliver tailor-made solutions for every company.” At the Open House, the 400 mm line for gas pipe extrusion delivered high outputs and top performance. The solEX 75 single screw extruder presented has, as standard, an AC motor that saves 20% energy compared with a DC motor and achieved outputs of 1,200 kg/h with a low noise level of below 80 db. The proven helix 400 VSI-T pipe head with inner pipe cooling EAC (efficient air cooling) ensured excellent melt homogeneity and pipe quality, with minimized sagging. This is why the combination of solEX and helix VSI-T is also ideal for large diameter solid wall PO pipe extrusion – diameters up to 2.6 m are currently possible. The inner cooling in the pipe head also enabled an impressive 45% reduction in line length from 85 m to 47 m. The PE material BorSafe 3490LS was sponsored by Borouge and the dehumidifying and conveying system came from Piovan. This energy reclaim system was used for pre-heating of the material, saving 30% energy, bringing the line’s combined energy consumption per ton of PE processed down to only 268 kWh. The 400 mm PE-RT line was sold to Hebei BlucicinPlastic Industry Co. Ltd., located at Guan, Hebei Province, before the Open House. The Chinese company produces PVC pipe, PPR pipe, PE pipe, PB/PBOB pipe and also bought the first 32 mm PBOB pipe line produced at battenfeld-cincinnati China in 2013. The second line on display was a LeanEX line, which is available in five sizes: 63, 160, 250, 400 and 630 mm. The LeanEX concept stands for “lean extrusion”, i.e. simple, turnkey lines for standard PO pipe applications built with European technology and locally sourced screws, barrels, motors and drives. The line shown was a LeanEX 63 mm line with a LeanEX C1-60-30 single screw extruder producing a PE-RT pipe with dimensions of 20*2.3 mm at the high line speed of 40 m/min and an output of 320 kg/h. The HDPE XSene XRT 70 / PE-RT Type II material for this line was sponsored by Total Refining & Chemicals. Source: battenfeld-cincinnati Previous news |

© 2002—2025 PLASTINFO