| MAIN |

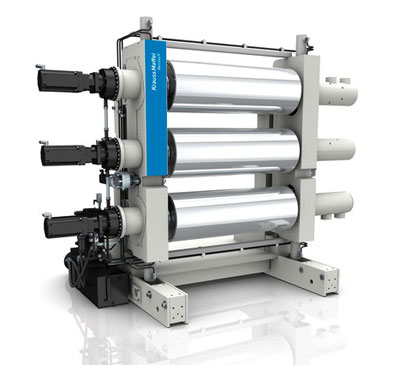

KraussMaffei Berstorff underpins its competence in direct extrusion| Subj: Press-releses  On the occasion of NPE 2015 in Orlando (23 ‑ 27 March 2015, West Hall, level 2, stand W 903), KraussMaffei Berstorff will exhibit various direct extrusion solutions. The systems presented on the stand will allow extrusion companies to hone their competitive edge in the production of pipes and sheets by reducing raw material and energy costs. On the occasion of NPE 2015 in Orlando (23 ‑ 27 March 2015, West Hall, level 2, stand W 903), KraussMaffei Berstorff will exhibit various direct extrusion solutions. The systems presented on the stand will allow extrusion companies to hone their competitive edge in the production of pipes and sheets by reducing raw material and energy costs.Direct extrusion for enhanced cost-effectiveness “Direct extrusion solutions for sheet and pipe production are gradually picking up steam and we are faced with a continuously increasing demand,” explains Matthias Sieverding, head of extrusion technology at KraussMaffei Berstorff in the USA. “To us, direct extrusion is no longer a quality issue, but a question of cost-effectiveness. When combined with our twin-screw extruders, KraussMaffei Berstorff direct extrusion solutions offer extremely promising business opportunities.” Twin-screw extruders feature high flexibility in the processing of compound formulations based on low-cost starting materials and are designed to shape a wide variety of different products in a single cycle. Application-tailored twin-screw extruders “The ZE A 60 UTXi twin-screw extruder displayed on the KraussMaffei Berstorff stand is available in different versions ‑ from a compact extruder for various compounding tasks up to a long machine equipped with side feeders, degassing openings and injection nozzle for special processes,” adds Matthias Everding. “Thanks to the multitude of different housing and screw elements, each machine can be tailored perfectly to specific customer requirements. This gives plastics producers higher flexibility and enhanced productivity.” As the modular screw configuration is easy to change, the twin-screw extruder can be quickly adapted to different process tasks. New 3-roll polishing calender for the production of thermoforming sheet At NPE 2015, KraussMaffei Berstorff will also present the new 3-roll polishing calender designed for sheet widths ranging between 800 and 1,200 mm and sheet thicknesses between 0.4 and 1.4 mm. This polishing calender is intended for producers of single or multi-layer PP, PE or PS film and sheets and ensures high productivity and cost-effectiveness through short set-up times. The polishing calender comes with extensive standard equipment, unparalleled user-friendliness and an attractive price/performance ratio. “An ever increasing number of customers identify the high potential for added value offered by direct extrusion of thermoforming sheet,” says Matthias Sieverding. “The combination with a twin-screw extruder reduces raw material cost by more than 0.3 euros per kilogram,” he adds. Pipe extrusion die designed for the efficient production of multi-layer pipes “The spiral mandrel die is a highly innovative, extremely flexible and complex system tailored to a wide variety of different applications. Many of our customers want to produce pipes with filled central layer to save material cost, for instance. At the same time, there is a growing demand for pipes with resistant internal layer for drinking water applications with high chlorine content. In addition, the combination of radial and helical spirals in this solution ensures the production of thin layers with high precision and minimum wall thickness tolerances,” explains Matthias Sieverding. The displayed KM-3L RKW 74-250 IPC is equipped with an efficient internal pipe cooling system, which provides for inside cooling in addition to conventional cooling from the outside. This solution enables processors to increase the output rate by up to 60 per cent or, alternatively, to reduce the cooling section length by about 40 per cent. Source: KraussMaffei Berstorff Previous news |

© 2002—2025 PLASTINFO