| MAIN |

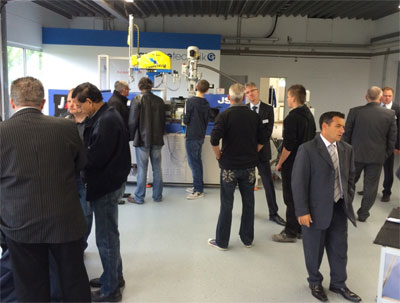

Groche Technology Days, 11 and 12 September 2014 in Kalletal/Germany| Subj: Press-releses  Armin Groche, Managing Director at Groche Technik in Kalletal has developed the first active non return valve up to the point of it now being ready for production – after three years of development work. A good reason then to allow interested experts to take a look at the world of this professional high-tech screw technology company during its open house event. Almost 150 visitors used this opportunity on 11 and 12 September 2014, with the new active non-return valve being the main focus of interest. Armin Groche, Managing Director at Groche Technik in Kalletal has developed the first active non return valve up to the point of it now being ready for production – after three years of development work. A good reason then to allow interested experts to take a look at the world of this professional high-tech screw technology company during its open house event. Almost 150 visitors used this opportunity on 11 and 12 September 2014, with the new active non-return valve being the main focus of interest. A number of other companies took up an invitation to exhibit their newest products in a new 1,400m² hall, put into use in January 2014: WINDSOR/JSW injection moulding machine, Campetella Robotic Center, Simatec with its driers and vacuum conveyors, Hummel with hot runner control technology, S+S with metal separators and a co-operation partner from Florida that makes screws extremely resistance with special coatings. Groche celebrated its 40th anniversary in 2010 and the company and its sales network of 22 representatives in 17 European countries meanwhile serve and advise injection moulding and extrusion processing companies in the area of high performance screws barrels and accessories. The new active non-return valve can be seen on the Groche stand during FAKUMA – Hall A6, Stand 6306. Success with new developments According to Armin Groche, credit goes to his customers for new developments. The discussions during which they come to him with their problems are as conclusive for the company chief as they have always been. Many solutions have been worked out with his customers in this way, and this know-how forms the company’s capital in competence today. The new non-return valve, the first “active” one ever, now adds further to this competence. After three years of development and evaluation, it is now running in pilot trials at several well-established customers. The particular feature of the active non-return valve lies in its tip. It is here where the plasticized melt stream is stopped at exactly the right point “end of dosing”, without complex use of electric motors or other pieces of equipment. This achieved with a special spring and bolt device that locks the non-return valve entirely before melt injection into the mould occurs. See and understand Professionals among Groche’s customer base wanted to see the working principle of the active non return valve. There was an all-electric drive J55AD injection moulding machine from WINDSOR/JSW busy working in the new hall no. 3, producing business card holders with high precision: Groche had bought the machine several months beforehand in order to demonstrate its special equipment (barrels and screws). And this was due to no small extent to Hummel hot runner technology. A multi-axial Campetella robot took care of part removal and placement on a MTF conveyor belt. Groche has expanded once again since its 40th anniversary. The third hall was added – to create workplaces for 10 further employees, make live demonstrations to customers of special equipment and to store numerous special barrels and screws. Armin Groche and his father Rolf Groche, the company founder, as well as the sales experts of the 50 strong company conducted the visitors in small groups through the three factory halls with their total area of 5000m² – through departments dealing with design, production process scheduling, CNC machining, assembly and quality control. Many stops were made on the way in the 2,000 square metre hall no. 1 to meet the need for discussions. Whether whirling technology, 6-axis CNC turning, tungsten inert gas welding (TIG) cabins or fine grinding stations, there were no unresolved questions left over at the end. The visitors, most of whom belonged to medium-sized companies involved in all injection moulding areas – from automotive, through packaging, electrical right up to medical areas – obtained an opportunity to talk shop with Groche experts about 3D CAD design, CAM computer-based production process scheduling and computer integrated manufacturing (CIM). Everything came up in discussion: CNC turning, CNC milling, CNC whirling, high-precision drilling, honing, surface grinding, external cylinder grinding, as well as plasma powder build-up welding, TIG welding, and vacuum tempering. “For customers, the focus is always on efficiency”, advises Groche, “particularly in areas in which increasingly aggressive materials are used, such as glass fibres and flame retardants”. In order to optimise wear and corrosion resistance, the screws and barrels can be provided on request with hard facings and coatings. Special alloys such as Hastelloy or Inconel are needed with some special applications. Special surface treatments such as nickel plating, hard chroming or (PVD) are available on request. The latter, physical vapour deposition, with which a coating is applied to a product with a plasma vapour, can optimize the service interval of a component by up to 60% - not to a small degree due to the higher surface height. “With screws coated at 750 m/sec by HVOF (high velocity oxygen fuel) flame spraying, which represents the “non plus ultra” in long life and ability to resist aggressive ingredients contained in plastic materials, a lot depends on the base material”, says Armin Groche, “so we have therefore made trials with our partner in Florida with special steels that themselves exclude any possibility of coating removal right from the start”. Broad specialisation Groche also develops new screw geometries in cooperation with the known producers of e.g. TPU, PMMA, PC, POM etc, as well as suppliers of special high temperature compounds and glass fibre reinforced materials. “After all, we serve demanding customers: 70% in the injection moulding market and 30% in the extrusion, LSR, thermosetting plastics and rubber industries – and this mainly Europe wide, plus 20% to overseas customers. 1,000 complete screw-and-barrel units and around 5,000 single special items such as non-return valves or mixing nozzles in different designs and dimensions go though the quality assurance (QA) department each year for despatch throughout the world” says Armin Groche in conclusion of the subject. Source: Groche Previous news |

© 2002—2025 PLASTINFO