| MAIN |

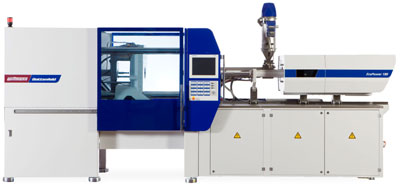

WITTMANN BATTENFELD: Hi-Q Shaping – injection embossing further developed| Subj: Press-releses  Due to its complete automatability, high reproduction accuracy and minimal need for downstream finishing of molded parts, injection molding ranks among the most important manufacturing processes in plastics processing, and serves as the basis for many specialized variants of this technology. Due to its complete automatability, high reproduction accuracy and minimal need for downstream finishing of molded parts, injection molding ranks among the most important manufacturing processes in plastics processing, and serves as the basis for many specialized variants of this technology.But particularly strong directional orientation must normally be expected in injection-molded parts, since in this process shaping is accompanied by major deformation, high deformation speeds and high-speed cooling; consequently, some of the molecules solidify with an orientation in the direction of the deformation. This leads to significant anisotropy in the attributes of injection-molded parts. However, components with attributes as isotropic as possible are increasingly required, in order to achieve the best possible surface quality and highest accuracy in shape and dimensions on the one hand, and on the other hand to keep warpage, internal tension and orientation at a low level. Optical parts are particularly sensitive to anisotropy, since internal tension and orientation strongly diminish the optical brilliance due to the effect of birefringence. This can only be remedied by applying a special form of injection molding, i.e. injection embossing. In this special process, the plastic melt is injected into a mold with a pre-defined embossing gap, then shaped by means of a pre-set compression stroke of the mold halves. Here, two different processes are in common use: • complete filling of the cavity • partial filling of the cavity Due to the high cooling speed inside the mold, injection embossing of thin-walled components and micro parts is largely restricted to the process with complete filling of the cavity. A compression stroke with partial cavity filling and an already frozen melt front would lead to surface defects and to the internal tension and orientation which should actually be prevented. Injection embossing is characterized above all by low material shearing and orientation. As the holding pressure is not applied via the gating, but becomes effective across the entire projected surface of the component, this leads to a reduction in sink marks. An improved venting effect due to injection into the open cavity can also be observed. Of course this requires a higher amount of capital investment in custom-built molds and a specially adapted process control system. The decisive processing step in injection embossing is primarily the application of the compression stroke. In conventional embossing processes, this stroke is time- or path-controlled, which leads to relatively low precision of the entire process in the area of micro parts, since time and path settings only allow a rigid process without information feedback from the molded part. Information about the thermodynamic states of the material inside the cavity and information feedback from the mold would make it possible to use a process specially adapted to the material processed. In this way, adjustments can be made to the specific behavior of each material during the embossing phase in order to ensure a dynamic, flexible and material-preserving process. The micro injection molding department of WITTMANN BATTENFELD has been engaged in developing such a dynamic injection embossing process for some time, in order to provide the improvement in quality demanded by the market. Thanks to its flexibility, reproduction accuracy and dynamism, the MicroPower machine model serves as an ideal platform for studies and tests in this field. The main goal of this latest development is to implement an extremely rapid, optimized injection-embossing process, in order to establish low-cost mass production of parts with nano-structured surfaces and improved material attributes. Development of Hi-Q Shaping at WITTMANN BATTENFELD With these objectives in view, Hi-Q Shaping was developed at WITTMANN BATTENFELD under the FP7 EU research program “Cotech” in cooperation with Microsystems UK, the Karlsruhe Institute of Technology KIT, the University of Bradford, the Technical University of Denmark DTU and the Department of Microsystems Engineering IMTEK at the University of Freiburg. For this purpose, a new software was created and adapted to the MicroPower injection molding machine. Hi-Q Shaping by WITTMANN BATTENFELD is a process in which, similar to conventional injection embossing, the active movement of the clamping unit during the injection process plays a major part. In this innovative process, the reference input variable or reference value is extended by adding temperature and pressure values, which enables specific regulation of the embossing pressure (holding pressure) for every process via the closing stroke. The aim is to apply the embossing pressure to the entire surface of the part above the glass transition temperature with a high degree of dynamism and precision. In this way, a drastic reduction in material tension becomes possible, since the deformation proceeds at significantly lower shear speeds. High dynamism combined with ultimate precision is necessary, because micro parts solidify much faster than larger parts due to their small size/thickness, which reduces the time window for the compression stroke to a fraction. Therefore the viscosity of the melt is automatically taken into account at every stage. Thanks to its extremely rigid toggle design, which is free of play but still permits high precision, the MicroPower is able to perform extremely accurate movements of the clamping plates and consequently precise compression strokes. Where micro structures are involved, the precision of the clamping stroke has an enormous influence on the pressure behavior inside the part. Due to the lower volume and small surfaces, the temperature conditions are much more critical than for larger parts. This is a highly dynamic embossing process which can only be implemented with adequate software, control technology and machine performance. In the tests, flashlight lenses were used as exemplary trial specimens, since these require high quality standards for the optical attributes and surface properties of the molded parts. These lenses were manufactured from the polymer Makrolon LED 2045, a polycarbonate with extremely high light transmission. Besides the PVT phase diagram, the effective temperature conductivity aeff and the glass transition temperature TG must be considered as additional important material parameters, since they make it possible to calculate the actual melt temperature at any point in time and thus make the process controllable in the first place. Specification of the final part dimensions and the desired density is also required. Birefringence effects were used to obtain information about internal tensions and orientations. Birefringence designates the proneness of optically anisotropic media to split a light beam into two beams polarized perpendicular to each other. A birefringent material is identified, for example, by using a polarization microscope. When the specimen is rotated between crossed polarization filters, the light intensity and/or color of a birefringent object will change, while optically isotropic materials show no change in their appearance. Conclusions about the surface quality of parts produced can be drawn by using comparative light microscopy. Summary of results This new, innovative process makes it possible to produce parts with a constant weight, minimal shrinkage, excellent surface quality and a low level of orientation and internal tension. The following main factors influencing the quality of the molded parts have been established: • mold temperature • compression force • compression time The tests have revealed that this process yields a higher degree of precision than standard embossing. Moreover, it was possible to reduce the internal tension and thus to achieve a significant improvement in translucency. Moreover, the cycle times in Hi-Q Shaping are virtually on a par with those in conventional injection molding and consequently ten times as fast as those in similar variothermic processes. This fact makes the process extremely economical and energy-efficient, as no high capital investment in a complex heating and cooling system for any comparable parts quality is necessary. Use of the injection embossing process generally leads to an improvement of both optical attributes and surface quality. Source: WITTMANN Battenfeld Previous news |

© 2002—2025 PLASTINFO