| MAIN |

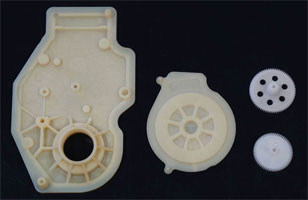

Wittmann Battenfeld: He who seeks shall find| Subj: Press-releses  That “standard” injection molding is not necessarily a boring routine without any potential for improvement is the conclusion that suggests itself from a visit to the Klagenfurt subsidiary of the Magna group of automotive suppliers. There, a dedicated team of engineers has scoured the entire production system for efficiency reserves and finally found them. The decisive point was the comparison of efficiency between two machine systems with differing proportions of servo-electric drive technology. The EcoPower machine from Wittmann Battenfeld had the winning edge. 5 to 8 per cent gain in cycle time, lower energy consumption and a comparatively good price/performance ratio tipped the balance in its favor. That “standard” injection molding is not necessarily a boring routine without any potential for improvement is the conclusion that suggests itself from a visit to the Klagenfurt subsidiary of the Magna group of automotive suppliers. There, a dedicated team of engineers has scoured the entire production system for efficiency reserves and finally found them. The decisive point was the comparison of efficiency between two machine systems with differing proportions of servo-electric drive technology. The EcoPower machine from Wittmann Battenfeld had the winning edge. 5 to 8 per cent gain in cycle time, lower energy consumption and a comparatively good price/performance ratio tipped the balance in its favor.Housing parts and gearwheels for stepping motors are manufactured In the injection molding shop of the Klagenfurt plant of Magna Auteca AG, which was newly constructed in 2008 (Fig.1). The technical standard of the parent company was maintained in the original installations for Magna Klagenfurt’s injection molding department. This means that production began with hybrid injection molding machines equipped with hydraulic, tiebarless clamping units and injection units with servo-electric drives (Fig.2). All machines are designed for fully automatic, continuous unmanned operation. To this end, all machines are equipped with a parts stacking system which has sufficient capacity to separate and stack the molded parts from multi-cavity molds. The parts transfer between the mold and the stacking system is handled by a linear robot, which passes the molded parts on to the separating device. That device’s main component is a pipe system whose number of pipes equals the maximum number of cavities of the molds in use, e.g. 8-cavity molds. It transfers the parts to individual parts stacking units in the form of product bags. To maximize the times of unmanned operation, the parts stacking unit is designed as a “twin configuration”, which means that two identical separating stations are placed directly side by side within the robot’s operating range. As soon as stacking unit number one holds a pre-set number of parts, the system automatically switches over to the ejector position for stacking unit number two. For final release of the production batches, which have been separated according to cavities, for downstream processing, Magna uses an SPC (statistic process control) system with spot checks. Thorsten Lutschounig, responsible for application technology and product quality, describes the high quality standards in Magna injection molding production as follows: “Magna sets the bar very high in calculating its reject rate. For our total production quantity also includes the start-up parts, although they are sorted out. This increases our reject rate. Consequently, low reject rates are not only an indicator for the quality and state of repair of the molds and injection molding machines, but also for the ability of the machine technology to reach stable production cycles quickly. Although we had already consistently reached excellent reject rates, we did not want to be satisfied with that. After all, it should be possible to accelerate production still further without having to compromise on quality standards.” The “all-electric machine” – a source of efficiency These thoughts prompted Magna to search for alternatives in manufacturing technology. Mario Pföstl, graduate engineer and Head of Injection Molding at Magna Klagenfurt: “It is clear to us that a continuous cost-cutting process contributes substantially to long-term preservation of a production plant. In short: the next logical step was to address machine technology. In this context, we regarded a higher proportion of servo-electric drive components as a promising feature. With that in mind, we checked the market. We finally settled for the EcoPower machine series from Wittmann Battenfeld, which also offered a favorable price-performance ratio.” Magna Klagenfurt actually chose the machine model EcoPower 110/350 (110 tons clamping force / injection unit 350 with a 30 mm L/D 22 screw) combined with a Wittmann W821 linear robot, and the standard parts separating system used by the Magna group (Fig.3). The EcoPower model just mentioned is an all-electric machine with servo drives for all main movements (clamping unit including the ejector, and metering/injection carried out by the injection unit), which is also equipped with an encapsulated hydraulic component as drive unit for a fast mold clamping system, core pulls and contact pressure for the injection unit. Passing the acid test The results of the twelve-month comparison phase speak for themselves, as Thorsten Lutschounig confirms: “Thanks to the machine’s fast servo drives for all main movements and its higher potential for parallel movements, the movement times have been shortened by 5 to 8 per cent, with the mold cooling time remaining unchanged. And this was achieved although the EcoPower with a 110-ton clamping unit competed with a lower clamping force against the existing hybrid machines. A very welcome side effect is that, due to their higher degree of efficiency, the servo drives consume less energy as well. Our ongoing comparative measurements will show us how much that is in terms of actual figures” (Fig.4). Source: WITTMANN Battenfeld Previous news |

© 2002—2025 PLASTINFO