| MAIN |

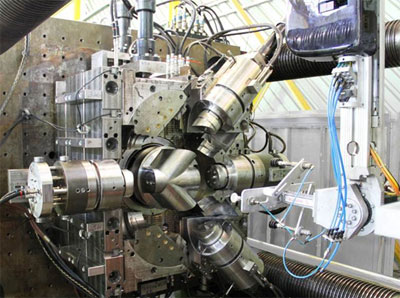

WITTMANN BATTENFELD at the K 2013: “Power for the Future” with the new MacroPower 1500| Subj: Press-releses  From 16 to 23 October WITTMANN BATTENFELD is presenting the largest MacroPower it has built so far to trade visitors at the K in Düsseldorf in hall 16, booth D22. From 16 to 23 October WITTMANN BATTENFELD is presenting the largest MacroPower it has built so far to trade visitors at the K in Düsseldorf in hall 16, booth D22.The MacroPower series – on display for the first time with the MacroPower 1000 at the K 2010 – has now been extended upwards by adding size 6, the MacroPower 1500. So the MacroPower series is now available in the full range of clamping forces from 400 to 1,600 t. The significant advantages of the MacroPower series – compact design, high speed, extremely easy operation and cleanness – are also outstanding features of the new MacroPower 1500. On the machine showcased at the K – a MacroPower 1500/8800 with ServoPower technology – a ground shaft will be manufactured from PP supplied by Borealis, Austria, using a mold from the Austrian mold maker ifw mould tec. The 4 pipe branch-off apertures are formed with the help of complex core-pull technology. The core pulls are equipped with P/Q valves. The finished part is demolded by means of an “interim core pull stop” in the opening stroke. The parts are removed and deposited in stacks by a WITTMANN W853 robot. Thanks to the 1600 x 1250 mm diagonal distance between tie-bars of the MacroPower 1500, the mold with its 4 core pulls can be fitted optimally into the machine. In the application demonstrated the durability of the product is of paramount importance in practical use. A product lifecycle of well over 50 years is assumed, which the product must survive underground without deformation or cracking. Special attention must be paid to optimal melt processing to prevent possible flaws. This is why high quality standards and reliability in particular are decisive criteria in ground shaft manufacturing in addition to efficient, low-cost production. The MacroPower 1500 equipped with the ground shaft mold from ifw mould tec is ideally suited to the production of this demanding application. The high performance and cost-effectiveness of the MacroPower 1500 are also the result of such features as its space-saving design, high speed and high energy efficiency, especially in the version with ServoPower drive on display. The high quality standard and reliability are also due to attributes such as the machine’s precision and ease of movement. This is an overview of the MacroPower 1500’s most important features: This machine stands out mainly by its short length and compact footprint, factors of particular significance in machines of this size. These attributes of the MacroPower, which are greatly appreciated by processors, have been achieved by the design of the 2-platen clamping system in combination with twin-cylinder injection aggregates, which are also extremely compact. Another highlight is the machine’s speed. It is the result of high traverse speeds and extremely short locking times reached by the innovative QUICKLOCK® locking system, which WITTMANN BATTENFELD has filed for patent. The locking system, which is integrated in the moving platen, also allows for a design with tie-bars of below-average length. In combination with an extended safety guard stroke at the rear of the machine, this makes it possible to insert a mold laterally from the rear without having to retract a tie-bar for lateral loading. Extremely large molds can also be inserted from the side in more than one part. This simplifies mold insertion and also reduces the costs, since no additional tie-bar pulling device is needed in most cases. If required, the machine can also be delivered with a core-pulling device as an option, which is able to retract or move out one tie-bar at the push of a button – a system which WITTMANN BATTENFELD has patented. This provides free space right up to the maximum mold height. The linear guides of the moving platen also deserve special attention, since they have dispensed with the oil pan which would normally be required to lubricate the sliding elements. Especially in large machines such as the MacroPower 1500, this feature is of special significance. Due to the low dynamic friction, the mold safety system in this machine is extremely sensitive, and the smooth running of the guides also contributes to the machine’s high energy efficiency. Moreover, the linear guides of the moving platen guarantee utmost precision, since they ensure exact platen parallelism across the entire stroke. As standard, the machines from the MacroPower series are driven by a 3-phase motor with electrically adjustable delivery pumps. As an option, and as demonstrated at the K 2013, they can also be equipped with a ServoPower drive system consisting of a highly dynamic servo motor and an electrically adjustable axial piston pump with variable displacement. In this system, the delivery is regulated via the motor speed and/or the pivoting angle of the hydraulic pump. In this way, the optimal combination of the pump’s degree of efficiency and the motor speed is calculated for each operating point and set via the machine’s control system. This enables energy consumption to be cut by an average of 30% with an average reduction of the sound level below 70 dba as well. Source: WITTMANN BATTENFELD Previous news |

© 2002—2025 PLASTINFO