| MAIN |

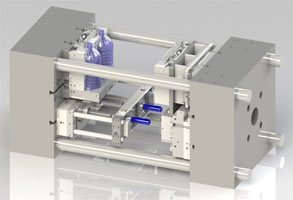

CYPET: Single-stage pet processing goes all-electric| Subj: Press-releses  PET processors finally have the possibility to produce any size of PET bottle up to 20 litres and any size of PET jar up to 145 mm neck diameter on an all-electric single-stage machine, with all the advantages of all-electric production as well as all the benefits of single-stage processing. CYPET Technologies Ltd has made this possible by introducing two all-electric machine models, based on its proprietary single-stage PET processing technology. PET processors finally have the possibility to produce any size of PET bottle up to 20 litres and any size of PET jar up to 145 mm neck diameter on an all-electric single-stage machine, with all the advantages of all-electric production as well as all the benefits of single-stage processing. CYPET Technologies Ltd has made this possible by introducing two all-electric machine models, based on its proprietary single-stage PET processing technology.The innovative CYPET single-stage process was originally implemented using energy-saving servo-hydraulic injection technology, with three machine models covering all sizes of PET bottles and jars production. Now CYPETís new all-electric machines will complement the three servo-hydraulic machine models that the company has on offer. Servo-hydraulic technology uses a servo motor to drive the hydraulic pump, so that by controlling the motor speed, the pump delivers accurately the oil pressure and flow that the machine requires, without any waste of energy. In addition to saving an estimated 30% of electricity usage, this technology has a faster response time and therefore a higher movement repeatability and process consistency, compared with conventional hydraulic technologies. Compared to servo-hydraulic technology, the primary advantage of all-electric PET processing is cleanliness, eliminating the risk of contamination from hydraulic oil leaks. There are, however, additional important benefits, like further savings in electricity consumption, the precision and repeatability of the process, the availability of parallel movements for saving cycle time and the lower maintenance requirements. CYPET claims that its all-electric machines offer all these important benefits at an affordable investment cost, resulting in a minimal effect on the total production cost of the PET containers. As a result, PET processors can offer PET bottles and jars to their customers at practically the same price, but with the peace-of-mind benefits of all-electric container production. CYPETís all-electric machines retain the unparalleled flexibility that its servo-hydraulic machines offer, with respect to the very wide range of sizes of PET containers that can be produced on a single machine model, by changing the moulds. Additionally, moulds change-over times remain much faster for both CYPET all-electric and servo-hydraulic machines, compared with conventional single-stage technologies. CYPET Technologies Ltd will be exhibiting at K-2013, in Hall 14, Stand C58. Source: CYPET Previous news |

© 2002—2025 PLASTINFO