| MAIN |

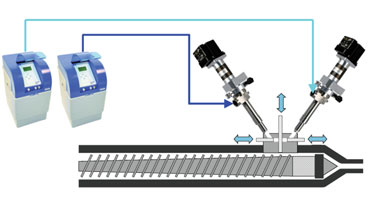

New technology modules from Sumitomo (SHI) Demag increase performance during injection moulding| Subj: Press-releses  At this year’s K trade fair, held in Dusseldorf on 16 - 22 October, Sumitomo (SHI) Demag Plastics Machinery will be presenting two technical modules for injection moulding on Stand D22 in Hall 15. These are activeColourChange, a pigment dosing system with extremely short colour change times, and the SL plastification system, which works without the usual compression zone and therefore, offers advantages in comparison with conventional plastification systems. Sumitomo (SHI) Demag provides injection moulders with a versatile assembly featuring tailor-made technology modules for efficient resource use. Here, the aim is to realise a high degree of production efficiency through interaction of the aspects durability, energy efficiency, availability and production performance. Two new technologies complement and expand the already existing very wide spectrum of technology modules. At this year’s K trade fair, held in Dusseldorf on 16 - 22 October, Sumitomo (SHI) Demag Plastics Machinery will be presenting two technical modules for injection moulding on Stand D22 in Hall 15. These are activeColourChange, a pigment dosing system with extremely short colour change times, and the SL plastification system, which works without the usual compression zone and therefore, offers advantages in comparison with conventional plastification systems. Sumitomo (SHI) Demag provides injection moulders with a versatile assembly featuring tailor-made technology modules for efficient resource use. Here, the aim is to realise a high degree of production efficiency through interaction of the aspects durability, energy efficiency, availability and production performance. Two new technologies complement and expand the already existing very wide spectrum of technology modules. activeColourChange – colour changes become extremely fast With activeColourChange, Sumitomo (SHI) Demag has developed a new, liquid-pigment dosing system, specially designed for injection moulding processing. Here, the pigment is dosed in a closed system directly into the melt-filled metering zone of the plastification unit. In contrast to pigmenting with Masterbatch, for example, the upstream zones (feedzone and compression zone) remain completely free of pigment. Thus, a considerably shorter screw length must be rinsed during colour change; compared with the use of Masterbatch, colour changes with activeColourChange are, therefore, extremely fast. The new pigment dosing and colour change system is designed for up to five colours. The switching on and off of pigment dosing is integrated into the machine control NC5 plus and is automated. Only a few cycles after beginning pigmentation, uniformly coloured pieces can be collected. Precise delivery pumps are used in activeColourChange so that even at high melt counter-pressure, the smallest pigment amounts can be added reproducibly. In order to ensure a very high homogenisation effect, the metering zone of the screw is equipped with a special mixing section. In this way, moulded parts with very high coverage can also be produced with low pigment amounts. This, in the end, has a positive impact on the cost. Additionally, less waste is generated through the considerably shorter colour change-over period required with activeColourChange - and, as a whole, the machine availability is increased for the profitable production of pieces. The new SL plastification system – plastification without compression The important process characteristic with which the new SL plastification system sets itself apart from the conventional plastification systems of an injection moulding machine, is the low feed plastification screw without compression zone. Material feed is controlled using an upstream dosing screw. The optimum filling level is determined by the material properties and the process parameters. The added granulate is melted almost exclusively using an easily controlled heat supply via cylinder heating of the plastification screw. In comparison with conventional plastification systems, the SL plastification system offers considerable advantages. An important reason for this is that the controlled operation results in the production of a very homogeneous melt without variations in viscosity. As a result, process variations and thus variations in the product quality are reduced. In combination with a switch-controlled non-return valve, the plastification without compression is particularly effective during the production of technical precision-moulded parts. Further advantages are also offered by the SL plastification system when there is high demand placed on product purity, for example, during injection moulding of optical components. The SL plastification system is currently available in serial production as an option for the fully-electric machines of the series SE-EV, which Sumitomo (SHI) Demag offers in the clamping force range of 500 to 1,800 kN. The new system will be demonstrated on the K trade fair stand as an example of precision injection moulding using an SE 180 EV (clamping force 1,800 kN). With a double mould, housing components for a smartphone will be produced from ABS/PC blend; injection weight is 45 g, cycle time 25 s. Source: Sumitomo (SHI) Demag Previous news |

© 2002—2025 PLASTINFO